When building a nitrous system, the fuel delivery system is the unsung hero that ensures your engine makes power reliably instead of becoming a cautionary tale. A robust Aeromotive fuel pump is the cornerstone of this setup, providing the necessary volume and pressure to support the additional fuel demand when the nitrous is activated. Choosing the right pump and supporting components is not just about maximum horsepower; it’s about precision, consistency, and safety under extreme conditions.

This roundup is designed to guide you through Aeromotive’s top-tier offerings, from complete in-tank kits to high-flow external pumps and critical regulators. We will break down the key features and benefits of each product, helping you identify the perfect component for your specific build, whether you’re running a carbureted setup or a sophisticated electronic fuel injection system. The right fuel system investment protects your engine and unlocks the full, repeatable potential of your nitrous oxide system.

Our Top Aeromotive Fuel System Picks

- Aeromotive 13113 Regulator, Single Spring Belt/Hex Drive EFI

- Universal Electric Fuel Pump Kit 12v 3-6 PSI Low Pressure

- A-Premium Electric Fuel Pump Module Assembly with Sending Unit

- Aeromotive 11101 Stealth 340 In-Tank Fuel Pump

- Aeromotive 11142 Phantom 340 In-Tank Fuel Pump Kit

- Aeromotive 11150 A1000 Fuel Pump

- Aeromotive 11152 A1000 Fuel Pump Kit with Regulator

- Aeromotive 11193 Stealth 340 In-Tank Fuel Pump Kit

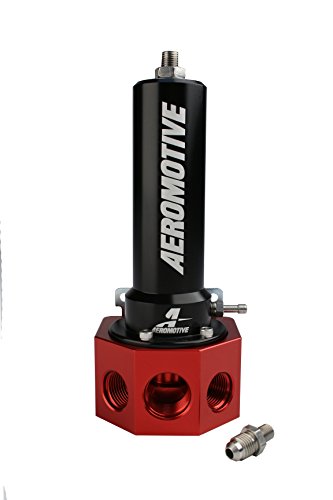

Aeromotive 13113 Regulator, Single Spring Belt/Hex Drive EFI

This mechanical fuel pressure regulator is a critical component for high-performance EFI systems, particularly those using a belt- or gear-driven pump. It is engineered to handle the immense flow rates—over 200 gallons per hour—required by powerful nitrous-assisted engines. The robust construction ensures it can manage the demands of pumps that develop significant pressure.

The 13113 offers a base pressure range of 40 to 100 PSI and features a 1:1 ratio reference for vacuum and boost. This means fuel pressure rises and falls directly with manifold pressure, maintaining a consistent fuel delivery differential. Included adapters for both rubber hose and AN-04 braided line make installation straightforward and secure, preventing line blow-off in high-boost scenarios.

Universal Electric Fuel Pump Kit 12v 3-6 PSI Low Pressure

This universal low-pressure electric pump serves as a reliable solution for carbureted applications or as a dedicated fuel supply pump for a nitrous system solenoid. Its 12-volt operation and compact design make it versatile for various installations, including small engines and fuel transfer tasks. The unit is designed for use with both gasoline and diesel, adding to its flexibility.

With an output pressure range of 3 to 6 PSI, it is perfectly suited for carbureted engines that require lower fuel pressure. The kit’s convenience is a major benefit, as it comes with a pre-filter and over 6 feet of 5/16″ fuel line. This all-in-one package simplifies the process of adding or replacing a fuel pump, saving time and effort during installation.

A-Premium Electric Fuel Pump Module Assembly with Sending Unit

For owners of specific Nissan and Suzuki models, this complete fuel pump module assembly offers a direct replacement solution. It restores proper fuel delivery and accurate fuel level reading, which is essential for daily drivers or vehicles used for performance. The module includes the pump, sending unit, and filter in one assembled package.

This product is designed for a direct fit, ensuring compatibility with the vehicle’s electrical connections and fuel tank mounting. It replaces several OEM part numbers, making it a versatile option for many 2005-2019 Nissan Frontiers, Pathfinders, Xterras, and Suzuki Equators. Using a complete assembly like this guarantees all components work together correctly for reliable operation.

Aeromotive 11101 Stealth 340 In-Tank Fuel Pump

The Stealth 340 pump is engineered for high-output fuel injection systems while maintaining an in-tank installation for quieter operation and cooler fuel. It is an excellent choice for street-driven performance vehicles that also see track or nitrous use. This pump can support high horsepower levels, making it a popular upgrade for modern muscle cars and trucks.

Its brushless motor design contributes to long-term durability and consistent performance. The “Stealth” name is well-earned, as it is significantly quieter than many external high-flow pumps. This allows for a high-performance fuel system without the typical noise associated with racing fuel pumps, preserving the vehicle’s driveability and comfort.

Aeromotive 11142 Phantom 340 In-Tank Fuel Pump Kit

This kit takes the performance of the Stealth 340 pump and packages it with everything needed for a complete in-tank installation in a factory-style fuel tank. It is the solution for vehicles that lack an in-tank pump or for those looking to convert from an external setup. The Phantom line is known for its innovative, adjustable design that fits a wide range of tank depths.

The kit includes the pump, a durable housing, a high-quality filter, and the necessary hardware for a professional installation. The adjustable length feature allows the unit to be tailored to the specific fuel tank, ensuring optimal pickup and function. This makes it a universal solution that performs like a custom-fitted part, ideal for restomods and custom projects.

Aeromotive 11150 A1000 Fuel Pump

The A1000 is a legendary external fuel pump known for its massive flow capacity and rugged reliability in all-out racing environments. It is a go-to choice for dedicated race cars, high-horsepower street machines, and vehicles with complex multi-stage nitrous systems. Its reputation for handling high pressure and volume is well-established in the performance world.

This pump is designed for continuous duty in extreme conditions and is capable of supporting engines well over 1000 horsepower. Its external mounting configuration makes it serviceable and accessible. While it is known for its performance, it is also known for its sound, making it best suited for vehicles where maximum fuel flow is the primary concern over noise levels.

Aeromotive 11152 A1000 Fuel Pump Kit with Regulator

This comprehensive kit provides a complete fuel system solution centered around the powerful A1000 pump. It includes the pump, an A1000 bypass regulator, an inline fuel filter, and all the necessary fittings and hardware. This takes the guesswork out of component selection and ensures all parts are designed to work together seamlessly.

For builders looking for a single purchase that covers the heart of their fuel system, this kit is an efficient choice. It is ideal for installing a new high-performance fuel system from scratch or upgrading an existing inadequate setup. The inclusion of the matching regulator is crucial for maintaining stable fuel pressure and getting the most out of the A1000 pump’s capabilities.

Aeromotive 11193 Stealth 340 In-Tank Fuel Pump Kit

This kit is designed for a seamless, high-performance upgrade in specific late-model GM vehicles, such as the Camaro and Corvette. It combines the Stealth 340 in-tank pump with a vehicle-specific fuel module hangar for a direct, plug-and-play installation. This allows for a significant increase in fuel system capability without any custom fabrication.

The benefit of this targeted approach is a perfect fit and retained factory functionality, including the fuel level sender. It provides the high flow needed for forced induction or nitrous systems while maintaining a stock appearance and noise level. For late-model GM performance enthusiasts, this is often the preferred method for upgrading the fuel system reliably and cleanly.

Buying Guide: How to Choose the Right Aeromotive Fuel Pump for Your Nitrous System

When you are building a nitrous system, the fuel pump is not a part you want to get wrong. It is the heart of your entire fuel delivery setup, and a weak heart means a weak run—or worse, a damaged engine. I have learned that choosing the right Aeromotive fuel pump comes down to understanding a few key things about your own setup.

First, you need to be honest about your power goals. This is the most important step. Are you aiming for a 150-shot of nitrous or a massive 400-horsepower hit? The fuel volume and pressure demands are completely different. Aeromotive rates their pumps in gallons per hour (GPH) at a specific pressure, usually 45 or 60 PSI. You need a pump that can supply enough fuel for your engine’s base horsepower plus the additional fuel required by the nitrous system. I always recommend choosing a pump rated for more power than you think you will make. It is better to have the capacity and not need it all than to run the pump at its absolute limit.

Next, consider your vehicle’s voltage. A pump’s rated flow is often based on a perfect 13.5 or 14 volts. In the real world, voltage at the pump can drop, especially during a hard launch. A pump that flows 340 GPH at 13.5 volts might only flow 300 GPH at 12 volts. That is a big difference that can lead to a lean condition. Look at the pump’s performance charts to see how it behaves at different voltages. For high-horsepower applications, I often suggest looking at pumps that can be run with a dedicated voltage booster or controller to ensure consistent performance.

You also need to think about the pump’s physical installation and whether you want an in-tank or an external model. In-tank pumps are generally quieter and benefit from being submerged in fuel, which keeps them cool. External pumps are often easier to service and can be a good choice if you are limited on tank space or are modifying an existing fuel cell. Aeromotive makes excellent options for both configurations. Finally, do not forget about the rest of your fuel system. A monster pump is useless if it is being fed by a tiny -6AN feed line or a clogged filter. Your entire system, from the pickup to the regulator, needs to be matched to the pump’s capabilities to support your 8 Best Aeromotive Fuel Pumps for Nitrous Systems setup properly.

Frequently Asked Questions

Can I use my stock fuel pump with a nitrous system?

I would strongly advise against it. Your factory fuel pump is designed to handle the fuel needs of your engine in its stock form. When you introduce nitrous oxide, you are also injecting a significant amount of additional fuel. The stock pump simply does not have the flow capacity to support both the engine and the nitrous system safely. Trying to do so will almost certainly cause a lean condition, which can lead to severe engine damage. Upgrading to a dedicated high-performance pump like an Aeromotive is a non-negotiable part of a safe nitrous installation.

What is the difference between a standard fuel pump and one designed for nitrous?

The main differences are flow capacity and durability. A pump built for nitrous applications is engineered to move a much higher volume of fuel, measured in gallons per hour (GPH), at the consistent high pressure that nitrous solenoids and foggers require. These pumps are also built with more robust internals to handle the constant high demand and are less likely to cavitate or lose pressure under load. Think of it as the difference between a garden hose and a fire hose; both move water, but one is built for a much more demanding job.

How do I know if my fuel pump is strong enough for my nitrous kit?

The best way is to do the math based on your horsepower. You need to calculate the fuel requirements for your engine’s naturally aspirated power plus the horsepower added by the nitrous. A good rule of thumb is that you need approximately 0.5 pounds of fuel per horsepower per hour. Compare this total to the flow ratings of the pump at your intended base fuel pressure and the voltage your car actually provides. It is also a great idea to monitor your air/fuel ratio closely on a dyno or with a dedicated gauge during your first few hits to confirm the system is working correctly.

Do I need a fuel pressure regulator with an Aeromotive pump?

Yes, absolutely. A good bypass-style regulator is essential. The pump will create more flow and pressure than your engine needs at any given moment. The regulator’s job is to send unused fuel back to the tank while maintaining a consistent, set pressure at the fuel rails and nitrous system. This consistent pressure is critical for accurate fuel delivery. Running without a proper regulator will cause erratic pressure, poor performance, and potential damage. Aeromotive makes regulators that are perfectly matched to their pumps for this reason.

Why does my Aeromotive pump seem so loud?

Some noise is normal for high-performance mechanical and external electric pumps. They are moving a lot of fluid with powerful internals, and that creates operational noise. An in-tank pump will usually be quieter because the fuel in the tank helps dampen the sound. If you feel the noise is excessive, check your installation. Ensure all fittings are tight and that the pump is mounted securely with the recommended isolators to prevent vibration from being transferred to the chassis, which can amplify the sound.