When building a nitrous system, the heart of your fuel delivery is non-negotiable. A weak or inadequate fuel pump can lead to a lean condition, causing catastrophic engine damage the moment you hit the switch. You need a pump that can deliver a massive volume of fuel under high pressure, consistently and reliably, to support the immense power gains nitrous oxide provides.

Aeromotive has built a legendary reputation in the performance world for engineering fuel system components that can handle the most extreme demands. From dedicated high-flow in-tank pumps to sophisticated regulators that manage pressure under boost, their products are designed to keep your engine safe while making big power. This roundup focuses on the best Aeromotive fuel pumps and key supporting components to ensure your nitrous-assisted build is both powerful and protected.

The Best Aeromotive Fuel Pumps for Your Nitrous Setup

- Aeromotive 13113 Regulator, Single Spring Belt/Hex Drive EFI

- Universal Electric Fuel Pump Kit 12v 3-6 PSI Low Pressure

- A-Premium Electric Fuel Pump Module Assembly with Sending Unit

- NOCO GENIUS1: 1A 6V/12V Smart Battery Charger

- Aeromotive 11540 340 Series Stealth Intank Fuel Pump

- Aeromotive 11142 Billet Fuel Pump Regulator

- Aeromotive 11150 A1000 Fuel Pump

- Aeromotive 11175 Eliminator Fuel Pump

Aeromotive 13113 Regulator, Single Spring Belt/Hex Drive EFI

For high-horsepower nitrous applications using a mechanical fuel pump, precise pressure control is critical. The Aeromotive 13113 is a belt or hex-drive regulator built specifically for this task. It is engineered to handle the immense flow of pumps delivering over 200 gallons per hour at EFI pressure levels, making it a robust cornerstone for a serious fuel system.

This regulator offers a wide base pressure adjustment range from 40 to 100 PSI and features a 1:1 ratio reference for vacuum and boost. This means fuel pressure rises directly with manifold pressure, ensuring the fuel injectors see a consistent pressure differential for optimal atomization. Included adapters for both rubber hose and AN-04 braided line provide secure connections that prevent blow-off under high boost, a common failure point in lesser units.

Universal Electric Fuel Pump Kit 12v 3-6 PSI Low Pressure

While not suitable for a primary nitrous fuel system, this universal low-pressure pump serves an important auxiliary role. It is designed for carbureted applications or for transferring fuel, operating at a mild 3-6 PSI. Its 12-volt design and included wiring make it straightforward to install for various low-demand tasks.

This pump can be useful in a nitrous setup as a dedicated fuel supply for a stand-alone fuel cell for the nitrous system itself, or for other small engines. It is compatible with both gasoline and diesel fuel. The kit includes a fuel filter and over 6 feet of fuel line, providing a complete solution for its intended low-pressure applications.

A-Premium Electric Fuel Pump Module Assembly with Sending Unit

This is a direct replacement fuel pump module assembly for several Nissan and Suzuki vehicles. For someone with a stock or mildly modified truck who is adding a small nitrous system, a reliable OEM-style replacement is sometimes the best choice. This unit restores factory performance and fuel level sender operation.

It is a direct fit for models like the Nissan Frontier, Pathfinder, and Xterra with 2.5L or 4.0L engines. The module comes as a complete assembly, which often simplifies installation compared to replacing just the pump. This makes it a practical solution for returning a daily-driven vehicle to reliable operation while supporting minor performance upgrades.

NOCO GENIUS1: 1A 6V/12V Smart Battery Charger

A consistent and strong electrical supply is vital for any electric fuel pump, especially under the high load of a nitrous pass. The NOCO GENIUS1 is a smart battery charger and maintainer that ensures your vehicle’s battery is always at peak condition. It provides peace of mind that your fuel pump will receive full voltage when you need it most.

This compact unit works with 6V and 12V lead-acid and lithium-ion batteries. Its integrated thermal sensor adjusts the charge based on ambient temperature to prevent overcharging or undercharging. By maintaining your battery’s health, this accessory indirectly supports the reliability of your entire high-performance fuel system.

Aeromotive 11540 340 Series Stealth Intank Fuel Pump

The Aeromotive 340 Stealth is a high-output in-tank pump that is an excellent choice for many nitrous-assisted street and strip vehicles. It delivers superior performance, exceeding standard flow rates by over 30% and providing more than 340 liters per hour at 40 PSI. This robust flow supports significant power adders without the complexity of an external pump setup.

Its compact and lightweight design allows it to bolt directly into many existing factory or aftermarket fuel hanger assemblies. This makes for a clean, OEM-plus installation that maintains factory lines and mounting. It is a versatile pump, perfect for forced induction and nitrous systems, and it supports the use of both gasoline and E85 fuels.

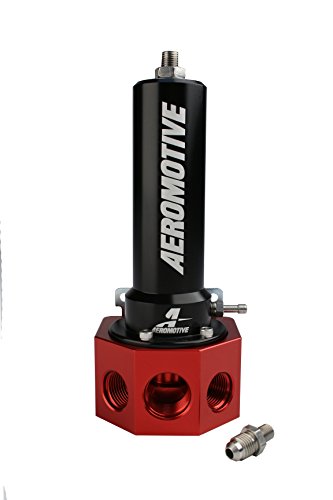

Aeromotive 11142 Billet Fuel Pump Regulator

The Aeromotive 11142 is a high-flow, billet aluminum fuel pressure regulator designed for performance EFI applications. Its precision-machined construction ensures reliability and consistent performance, which is fundamental for managing fuel pressure in a nitrous system. This regulator is built to handle the high flow demands of powerful engines.

It typically features multiple ports for a versatile installation, allowing for a fuel pressure gauge and multiple feed or return lines. Like other Aeromotive regulators, it operates on a 1:1 boost reference ratio to maintain proper injector pressure under boost. This component is a key part of a complete Aeromotive fuel system for serious horsepower.

Aeromotive 11150 A1000 Fuel Pump

The Aeromotive A1000 is a legendary external fuel pump known for its massive fuel delivery capabilities. It is a go-to choice for all-out race applications and extreme horsepower levels that dwarf most street nitrous systems. This pump can support engines making well over 1,000 horsepower, providing a margin of safety for the most powerful builds.

As a gerotor-style pump, it is known for its durability and ability to move a very high volume of fuel at a wide range of pressures. It is designed for use with a dedicated fuel cell and pre-filter, making it a central component of a professional-grade racing fuel system. For those building a maximum-effort vehicle, the A1000 is a proven performer.

Aeromotive 11175 Eliminator Fuel Pump

Sitting at the top of Aeromotive’s pump lineup, the Eliminator series is designed for the ultimate in fuel flow and system pressure. These pumps are intended for the most demanding applications, including professional drag racing and land speed record vehicles where fuel delivery cannot be a single point of failure.

The Eliminator pump represents the pinnacle of performance, capable of supporting multiple thousands of horsepower. It features a robust design built for continuous duty under extreme conditions. For a nitrous system on a dedicated race car aiming for the highest possible power levels, the Eliminator pump provides the ultimate foundation for fuel system design.

What to Look For in the Best Aeromotive Fuel Pumps for Nitrous Systems

When you are building a nitrous system, your fuel pump is not a part you want to guess on. It is the heart of your fuel system, and a weak heart means a weak run, or worse, a damaged engine. I have learned that picking the right Aeromotive fuel pump comes down to a few key things that go beyond just looking at the biggest number on the box.

First, you need to think about flow rate, but you have to be smart about it. It is not just about the maximum flow; it is about the flow at the pressure you will actually be running. Nitrous systems put a massive, sudden demand on your fuel system. Your pump has to be able to maintain both your base fuel pressure for the engine and the additional pressure required to feed the nitrous solenoid without dropping off. A pump that flows 340 liters per hour (LPH) at 45 psi might only flow 240 LPH at the 70-80 psi your nitrous system might need. Always check the pump’s performance chart to see its flow at your target system pressure.

Next, consider voltage. This is a big one that many people overlook. The voltage at your pump is almost always less than the 13.5 to 14 volts your alternator puts out. There is a drop through the wiring, relays, and connections. A pump rated at 1000 horsepower at 13.5 volts might only support 800 horsepower at 12 volts. I always plan for this by choosing a pump rated for more than my goal, and I make sure to use a high-quality relay and thick enough wiring to minimize that voltage drop. A dedicated, robust wiring kit is a non-negotiable part of the install.

Finally, think about the type of pump and how it fits your setup. Are you running a carburetor or fuel injection? This determines if you need a high-pressure EFI pump or a high-volume carburetor pump. Also, consider if an in-tank or an external inline pump is better for your car. In-tank pumps are generally quieter and benefit from being submerged in fuel, which keeps them cool. External pumps are often easier to service and can be a good solution for vehicles where an in-tank unit is difficult to fit. For a serious nitrous application, you might even see people using multiple pumps or a large main pump with a dedicated, smaller pump just for the nitrous system. Do not just pick a pump; design a fuel system that can handle the shock of the nitrous hit.

FAQ

Can I use my stock fuel pump with a nitrous system?

In almost every case, no. Your stock fuel pump is designed to support the engine in a naturally aspirated state. When you activate a nitrous system, you are dramatically increasing the engine’s demand for fuel almost instantly. A stock pump simply cannot keep up with this sudden surge, which will cause a lean condition. A lean condition under the high cylinder pressures created by nitrous is a surefire way to cause severe engine damage. Upgrading to one of the best Aeromotive fuel pumps for nitrous systems is a mandatory safety measure, not an optional upgrade.

How do I know what size Aeromotive fuel pump I need?

You need to calculate your total fuel requirement. Start with the fuel needs of your engine without nitrous, then add the fuel required for your nitrous shot. A common rule of thumb is that you need approximately 0.10 to 0.125 pounds of fuel per horsepower per hour. So, for a 500 horsepower engine with a 150-horsepower nitrous shot, you would need fuel for 650 horsepower. That is 650 hp x 0.10 lbs/hp/hr = 65 lbs/hr. Since there are roughly 6.5 pounds in a gallon of gasoline, this translates to about 10 gallons per hour (GPH), or roughly 38 liters per hour (LPH). This is a simplified calculation, and you must also ensure the pump can deliver this flow at your specific operating fuel pressure, which is why looking at the pump’s performance chart is so important.

What is the difference between an in-tank and an external fuel pump for nitrous?

In-tank pumps are mounted inside your fuel tank. The main benefits are that they are quieter and use the fuel in the tank to keep themselves cool, which improves their longevity and consistency. External pumps are mounted in-line, somewhere along the fuel line between the tank and the engine. They are often easier to access for service or replacement. For high-horsepower nitrous applications, many builders prefer in-tank setups for their cooling benefits, but robust external pumps like the A1000 are extremely popular and proven. The best choice often depends on your vehicle’s layout and your personal preference for installation and maintenance.

Do I need a fuel pressure regulator with an Aeromotive pump for nitrous?

Yes, absolutely. A high-quality fuel pressure regulator is a critical component. It does not just set your base fuel pressure; it must be able to react quickly and maintain a consistent pressure when the nitrous system activates. A good regulator, like many of Aeromotive’s own models, will have a large diaphragm and be designed to handle the rapid changes in flow demand. For nitrous systems, you often need to reference boost or nitrous pressure to the regulator to ensure the fuel pressure to the nitrous solenoid rises appropriately, maintaining the correct fuel-to-nitrous ratio.

Should I run a dedicated fuel pump for my nitrous system?

This is a popular and very effective strategy, especially for larger nitrous shots. Instead of asking one pump to do everything, you use your main pump to supply the engine and a separate, smaller pump dedicated solely to feeding the nitrous system. This isolates the systems and ensures that the nitrous system always gets the fuel volume and pressure it needs the moment it is activated, without robbing fuel from the engine. This is considered a best practice for high-performance and racing applications where reliability is key.