A loose or damaged kayak skeg can turn a peaceful paddle into a frustrating battle against the current. A strong, waterproof adhesive is the key to getting back on track with a repair that holds up against the elements. The right goop can mean the difference between a temporary fix and a permanent solution, ensuring your kayak tracks straight and true for seasons to come.

With so many marine adhesives and sealants on the market, choosing the best one for your specific skeg and kayak material can be overwhelming. This roundup cuts through the confusion to bring you the top-performing products designed for strong, flexible, and completely waterproof bonds. We have compiled a list of reliable options to help you make an informed decision for your next repair project.

The Best Adhesives and Skegs for Your Kayak

- 3.7 oz Eclectic Products Amazing Goop Marine Adhesive

- Goop Marine Adhesive and Sealant Clear 3.7 Oz

- New Goop 170012 3.7oz Marine Glue Adhesive Clear Water Prf Sealant

- DSHE Detachable Center Fin Black, Kayak Rudder Kit Skeg

- Kayak Skeg Tracking Fin Kayak Fin Mounting Points Watershed Board

- 3M Marine Adhesive Sealant 5200 Permanent Bonding and Sealing

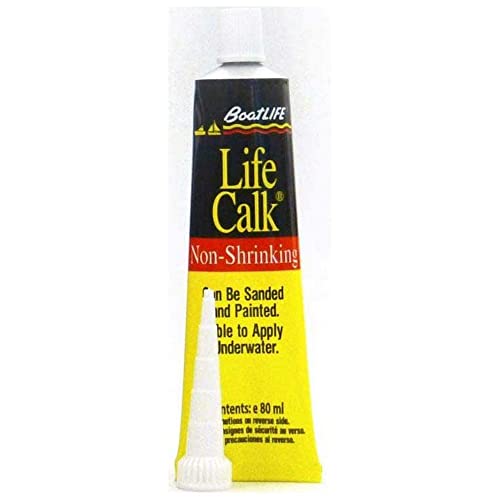

- BoatLIFE Life-Calk Sealant Tube – Non-Shrinking – Black

- G-Flex 650 Epoxy Adhesive Kit by West System

- Loctite PL Marine Fast Cure Adhesive Sealant

3.7 oz Eclectic Products Amazing Goop Marine Adhesive

This marine-grade adhesive from Eclectic Products is a trusted solution for a multitude of on-board repairs. It is formulated to create a strong, flexible, and completely waterproof bond that is essential for securing a kayak skeg. Its versatility allows it to adhere to various materials commonly found on watercraft.

The adhesive cures to a durable seal that can withstand constant exposure to water, sun, and vibration without becoming brittle or cracking. This makes it an excellent choice for the dynamic stresses a skeg endures. For a reliable all-purpose marine adhesive, this Goop product is a solid contender.

Goop Marine Adhesive and Sealant Clear 3.7 Oz

For a discreet repair that maintains the look of your kayak, this clear marine adhesive is an ideal option. It provides the same strong, flexible, and waterproof hold as other Goop variants but dries transparent. This feature is perfect for repairs where aesthetics are a consideration.

This formula is UV resistant and creates a flexible hold that will not crack or become brittle under stress or vibration. It is also paintable, allowing you to blend the repair seamlessly into your kayak’s hull if desired. Its clear and durable nature makes it a favorite for visible skeg mounting points.

New Goop 170012 3.7oz Marine Glue Adhesive Clear Water Prf Sealant

This version of the Marine Goop adhesive offers exceptional versatility for your repair needs. It is designed to work effectively on a wide range of materials including glass, plastic, metal, vinyl, rubber, and wood. This makes it suitable for attaching skegs to various kayak hull compositions.

As a waterproof sealant, it creates a robust barrier against moisture, ensuring your skeg remains securely fastened. Its flexibility is key for withstanding the impacts and pressures encountered during paddling. Consider this a highly adaptable adhesive for any marine application.

DSHE Detachable Center Fin Black, Kayak Rudder Kit Skeg

Sometimes the best solution is a replacement. The DSHE Detachable Center Fin is a universal skeg designed for inflatable canoes, SUPs, and kayaks. Its classic design provides an excellent balance of tracking stability and maneuverability, helping your boat hold a straight line in flat water while still allowing for turns.

Constructed from fiberglass-reinforced nylon composite materials, this fin is built to be strong and durable. It is engineered to offer a perfect balance of pivot and hold, which adds an extra layer of control and safety to your paddling experience. This is a great option if you need a new skeg altogether.

Kayak Skeg Tracking Fin Kayak Fin Mounting Points Watershed Board Canoe Large

This is a universal tracking fin designed to fit most kayaks. Its primary function is to improve tracking by dividing the water and decreasing water resistance, which helps the kayak move forward in a straight line with less effort from the paddler.

It is important to note that this skeg is made from PVC, so selecting an adhesive that forms a strong bond with PVC is crucial for a successful installation. When used with the correct adhesive, this fin can significantly enhance your kayak’s performance on the water.

3M Marine Adhesive Sealant 5200 Permanent Bonding and Sealing

When you need a bond that is meant to last a lifetime, 3M’s 5200 sealant is the industry standard for permanent marine repairs. This powerful polyurethane polymer is tough yet flexible, making it ideal for bonding a skeg to substrates like fiberglass, wood, and metal.

It is specifically engineered to resist saltwater and weathering both above and below the waterline. This product is for repairs where you do not intend to remove the skeg ever again, as it creates an extremely strong, permanent bond that is very difficult to break.

BoatLIFE Life-Calk Sealant Tube – Non-Shrinking – Black

BoatLIFE’s Life-Calk is a reliable polysulfide-based sealant known for its durability and flexibility. Its non-sag, non-shrinking formula ensures that it stays in place during application and cures to a consistent, watertight seal. This is crucial for ensuring a complete bond around the skeg base.

This sealant remains flexible after curing, which allows it to absorb the shocks and vibrations that come from hitting underwater objects. Available in black, it provides a clean, finished look for darker kayak hulls and is a trusted product for many marine sealing needs.

G-Flex 650 Epoxy Adhesive Kit by West System

For the most demanding repairs, the G-Flex 650 Epoxy Adhesive Kit offers an exceptionally strong and resilient solution. This epoxy is specially formulated to stick to a wide variety of materials and is known for its ability to withstand impact and flexing. It is an excellent choice for high-stress points like a skeg attachment.

G-Flex epoxy is durable, waterproof, and can be used on both rigid and flexible substrates. It is a two-part system that, when mixed, creates a permanent bond that is much stronger than typical sealants. This is the go-to for paddlers who want an industrial-grade, permanent fix.

Loctite PL Marine Fast Cure Adhesive Sealant

If you are looking for a quick and effective solution, Loctite’s PL Marine Fast Cure sealant is designed to get you back on the water sooner. This adhesive sealant cures quickly while still providing a strong, flexible, and 100% waterproof bond that is resistant to saltwater and weathering.

It is a versatile product that adheres to a wide range of boating materials, including wood, fiberglass, and metal. The fast-cure formula is a significant advantage when you need a reliable repair without a long waiting period for the adhesive to fully set.

Buying Guide: How to Choose the Best Adhesive Kayak Skeg Goop

When your kayak’s skeg gets damaged, finding the right adhesive is the difference between a quick, permanent fix and a recurring headache. I’ve fixed my fair share of skegs, and I’ve learned that not all “goops” are created equal. The best adhesive kayak skeg goop for strong and waterproof repairs needs to check a few critical boxes. Let’s talk about what really matters so you can get back on the water with confidence.

First and foremost, you need a flexible, waterproof bond. Your kayak’s hull and skeg are constantly flexing with wave action and impacts. A rigid epoxy might seem strong, but it can crack under this repeated stress. Look for marine-grade sealants and adhesives specifically designed to remain flexible after curing. Products like Marine GOOP or Sikaflex 291 are fantastic because they create a rubber-like seal that moves with the kayak, preventing cracks from reappearing.

Material compatibility is another huge factor. Most kayaks are made from polyethylene (PE), acrylonitrile butadiene styrene (ABS), or composite materials like fiberglass. Polyethylene is notoriously difficult to glue because it’s a “low-surface-energy” plastic. Standard adhesives just bead up on it. For PE kayaks, you absolutely need a plastic fusion adhesive or a specialized polyethylene primer used with a polyurethane adhesive. For ABS plastic or fiberglass, a two-part epoxy or a marine polyurethane adhesive will often work perfectly.

Consider the application process and cure time. Some products come in a convenient squeeze tube, while others require a caulking gun. Think about the size of the repair and how much control you need. Cure time is also crucial. A fast-setting adhesive might be tempting for a quick fix, but slower-curing options often create a stronger, more durable bond in the long run. Make sure you can keep the kayak undisturbed for the full curing period, which can sometimes be 24 to 48 hours.

Finally, don’t forget about sandability and paintability. If you want a smooth, professional-looking finish, you’ll need an adhesive that can be sanded down once it’s fully cured. Some products are also paintable, allowing you to color-match the repair to your kayak’s hull. This is more about aesthetics than function, but it’s a nice bonus if you care about the final look. By focusing on flexibility, material compatibility, and application details, you’ll find the perfect product to handle the job right.

FAQ

Can I use regular super glue or silicone caulk to fix my kayak skeg?

I wouldn’t recommend it. Regular super glue is far too brittle for the constant flexing and impact a skeg endures; it will crack and fail quickly. Standard silicone caulk from a hardware store also doesn’t have the necessary adhesive strength or long-term durability against water immersion and UV exposure. It might hold for a little while, but it’s not a permanent solution. You’re much better off using a product specifically formulated as an adhesive kayak skeg goop for strong and waterproof repairs.

How do I prepare the surface before applying the adhesive?

Surface prep is arguably the most important step for a successful repair. First, clean the area thoroughly with isopropyl alcohol to remove any dirt, grease, or biological film. If you’re repairing polyethylene, you need to “activate” the surface by lightly scuffing it with 80-grit sandpaper. This creates tiny grooves for the adhesive to grip onto. For a super-strong bond on PE plastic, using a plastic primer designed for polyethylene after sanding is a game-changer. It ensures the adhesive properly wets the surface and creates a powerful, lasting bond.

How long should the adhesive cure before I can use my kayak again?

This depends entirely on the product, so always check the manufacturer’s instructions. A “touch dry” or “tack-free” time can be as short as an hour, but that doesn’t mean it’s ready for the water. For a full, strong cure that can handle stress and immersion, you’re often looking at 24 to 72 hours. Temperature and humidity can affect this, with warmer, drier conditions speeding up the process. My rule of thumb is to wait at least 48 hours if possible. It’s frustrating to wait, but it beats having the repair fail in the middle of a trip.

What is the difference between a marine sealant and a marine adhesive?

This is a great question, as the terms are sometimes used interchangeably but they have different primary functions. A marine sealant is designed first and foremost to fill gaps and keep water out—its adhesive strength is secondary. A marine adhesive is engineered to bond two surfaces together with high strength, and its sealing properties are a bonus. For a skeg repair, you need a product that is a strong adhesive first, like a marine polyurethane (Sikaflex, 3M 5200) or a plastic fusion adhesive. These provide the structural strength to hold the skeg in place under force.

My skeg is made of a different plastic than my kayak hull. Does that matter?

It can matter a lot. If the skeg is a rigid plastic like ABS and the hull is flexible polyethylene, you need an adhesive that can bond to both and remain flexible. A stiff epoxy might bond well to the ABS skeg but could crack away from the PE hull. In this scenario, a flexible marine polyurethane adhesive is often your best bet. It acts as a flexible intermediary, creating a strong bond with both materials while absorbing the stress from their different flexing rates.